Introduction:

The VPCP series is a filtration and dehydration system specially designed for steam turbine oil by Viking Company. It integrates a precision filter with high efficiency dehydration of the oil, which can effectively remove particles, emulsified water and free water in the oil. After the treatment, the cleanliness of the oil can reach NAS1638 level 6, and the free water content can be less than 100 PPM.

Function of the device:

Filtration cycle: can be used alone as a particle filter device.

Dehydration cycle: It can remove emulsified water and free water in steam turbine oil.

Principle of the equipment

Filtering principle:

The oil flow through the high-efficiency filter element, through the filter element from the surface to the inside, along the flow direction gradually shrinking gradual pore structure, layered interception of different sizes of pollution particles, maximize the filter element's service life and filtering effect.

Dehydration principle:

After the oil flows through the filter FL02, it enters the coalescing filter element in the coalescing tank. Due to the unique polar molecules of the coalescing filter material, the free water and emulsified water in the oil coalesce to become larger after passing through the filter element. Water droplets. Due to gravity, it settles to the lower part of the coalescing tank. Part of the smaller water droplets move upwards with the oil under the action of inertia until the separation filter element.

The separation filter element is made of a special hydrophobic material. When the oil passes through, the water drops are blocked outside the filter element. After gathering each other, the size gradually increases, and finally settles into the water storage tank at the lower part of the coalescing tank due to gravity. . The oil enters the filter element and is discharged from the liquid outlet.

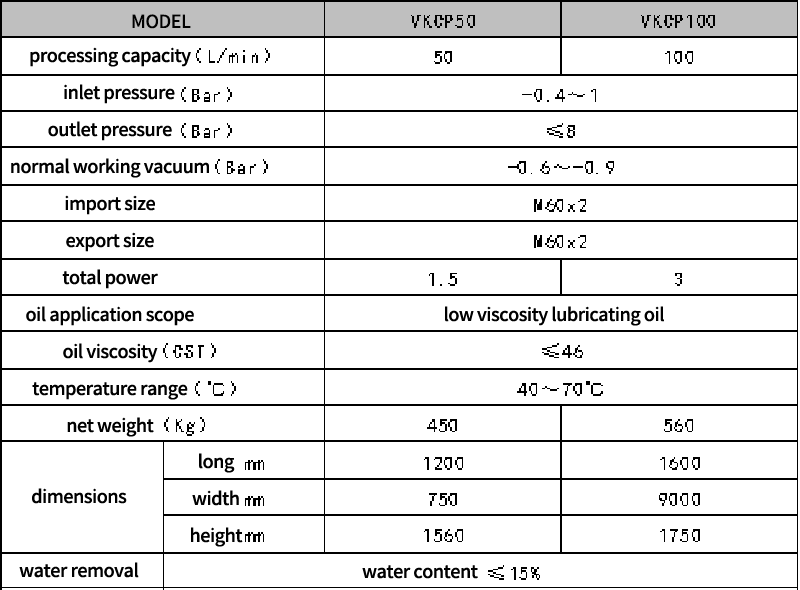

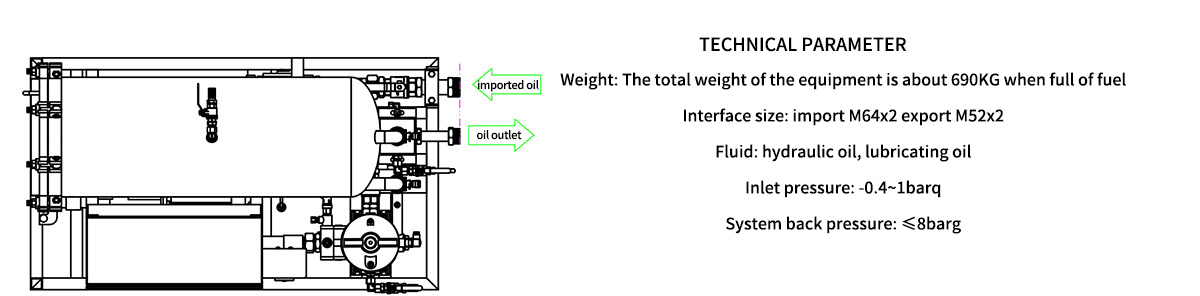

technical parameter: