Introduction: | Technical principle of high-efficiency coalescence and separation: | |

The core of Changzhou Viking OMB series high-efficiency oil de adopts "coalescing and separation" technology to remove oil mist in oil fume. The device integrates two functions of oil mist filtration and high-efficiency separation, which can effectively remove particulate impurities, atomized oil fume and water vapor in the flue gas. The function is divided into: centrifugal coarse separation, motion impact two-stage separation and high-efficiency coalescence separation three-stage separation multiple filtration technology. This device is specially developed for the lubrication system, which not only can effectively remove the oil mist and water vapor in the oil tank, avoid secondary pollution of the environment, and significantly reduce the consumption of lubricating oil, but also can ensure that the internal pressure of the oil tank is maintained at 0 when the fan stops unexpectedly. The overall design idea Advanced, has outstanding advantages compared with other brands. | The high-efficiency coalescence and separation filter element is composed of a variety of imported materials with different materials and characteristics. At present, the coalescence and separation materials used by Changzhou Viking are all products of famous foreign companies, which can ensure the use effect. Different materials have different filter gaps, surface tension characteristics, lipophilic/hydrophilic, oleophobic/hydrophobic polarities. Through the combined use of different materials, the three purposes of filtration, coalescence and separation can be achieved, so as to ensure the final separation effect. | |

Filter: | Coalescence: | |

In addition to oil fume, oil mist also contains various solid particles. The presence of solid particles will affect the effect of coalescence and separation, greatly reducing the service life of the filter element. Viking coalescing separation filter element designs high-efficiency deep filtration before the coalescing separation layer, and the flue gas can pass through the coalescence separation filter element after deep filtration, which greatly improves the life of the filter element. | Coalesce according to the surface tension of the medium. The coalescence layer is a multi-layer winding structure, composed of 3-4 materials. Through a specially designed gas channel structure, the structural change of the flue gas from small oil and gas to large oil droplets is realized. Viking coalescing separation filter element combines the core technology of PALL, with large throughput and strong coalescence ability. It can be used in harsh environments saturated with oil mist for a long time. It has advantages that traditional methods such as sintering method and felting method cannot match. |

Separation: | Discharge: | |

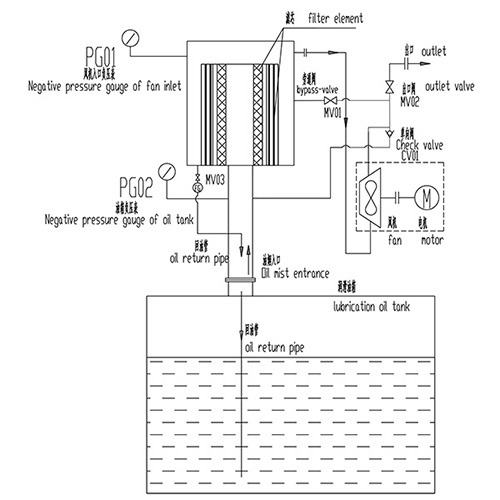

The flue gas passing through the coalescing filter element will enter the separation layer of the filter element. The large oil droplet moves forward under the drive of the gas, and collides with the separation layer due to the lipophilic/oleophobic polarity. Finally, due to gravity, the large oil droplet settles to the bottom of the container. | The oil separated by the oil fume fan is very clean and can be used directly back. Viking oil mist fan meets the design requirements of P&ID system diagrams of foreign oil stations. The oil discharge pipeline is specially reserved, and the pipeline penetrates below the minimum liquid level. |

System schematic diagram:

Technical Parameter

Name and model specification:

Serial number | Model | Motor Power | Ensure the negative pressure of the fuel tank |

1 | OMB180-0.75-150/80-SS | 0.75KW | -0.5Kpa |

2 | OMB210-1.1-150/80-SS | 1.1KW | -0.5Kpa |

3 | OMB350-1.5-200/80-SS | 1.5KW | -0.5Kpa |

4 | OMB420-2.2-200/80-SS | 2.2KW | -0.5Kpa |

5 | OMB500-4.0-200/80-SS | 4.0KW | -0.5Kpa |

6 | OMB700-5.5-300/100-SS | 5.5KW | -0.5Kpa |

7 | OMB900-7.5-300/100-SS | 7.5KW | -0.5Kpa |

Note:200/80 indicates the size of the inlet and outlet flanges of the oil mist separator. The specific flange dimensions, standards, etc. are made according to user requirements.

Working medium: oily air

Working conditions: installation on top of oil station, indoor or outdoor operation

Working speed: 2900rpm

System inlet pressure: -0.2~-0.5Kpa; Maximum allowable negative pressure: 10Kpa ;

Power condition: 380V 50Hz 3ph

Used to remove oil mist with high-efficiency gathering and separation method. The oil mist removal efficiency is ≥99.98%, and the oil particles in the oil fume are eliminated.

The upper cylinder and the lower inlet of the lampblack fan are equipped with a pressure gauge.

The inlet and outlet of the oil fume exhaust fan are provided with a bypass pipeline, which is connected with a manual stop valve to adjust the air supply of the fan.

Ensure that inlet is at zero pressure when the fan is stopped.

Table 3, Table 4 Examples of inlet/outlet size options

Code | Size description |

200/80 | Entrance sizeDN200 |

Export sizeDN80 | |

The specific import and export sizes and standards are selected by the user | |

Example OMB350-1.5-200/80-SS OMB

350-air volume (m³/min) 1.5-matching motor power

200/80-Oil mist fan inlet and outlet interface size

SS-Stainless Steel (CS Carbon Steel)

Special requirements (such as stainless steel SS316L, material prohibition of copper, etc.) please specify in the technical agreement.

Model description

OMB □E-□- □/ □- □

Table 1 Table 2 Table 3 Table 4 Table 5

Table 1, Table 2 Air volume-power options

Code | Guaranteed air volume | Code | Power description |

180 | 45m³/h | 0.75 | 0.75KW |

210 | 120m³/h | 1.1 | 1.1KW |

350 | 145m³/h | 1.5 | 1.5KW |

420 | 200m³/h | 2.2 | 2.2KW |

500 | 260m³/h | 4 | 4.0KW |

700 | 400m³/h | 5.5 | 5.5KW |

900 | 600m³/h | 7.5 | 7.5KW |

Table 5 Separator material options

Code | instruction |

CS | Carbon steel |

SS | 304 stainless steel |

Formulation of technical agreement for special material requirements(316L) | |

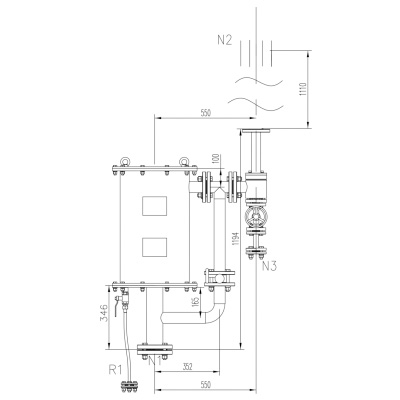

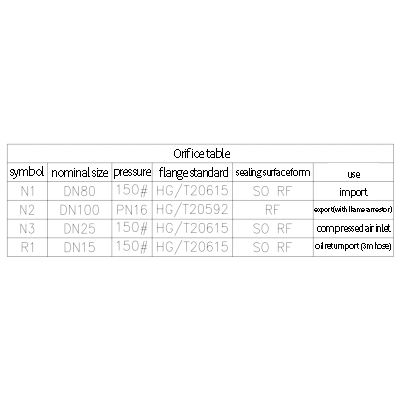

OMB type high efficiency appearance | ||||

The figure below is the outline dimension drawing of 0.75/1.1KW oil demister , N1, N2, R1 and other interfaces are provided according to the user interface | The figure below is the outline dimension drawing of 1.5/2.2KW . N1, N2, R1 and other interfaces are provided according to the user interface | |||

|

|

|

| |

|

| |||

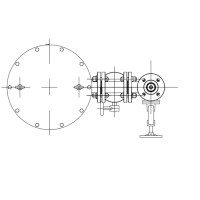

The figure below shows the dimensions of the 4KW , N1, N2, R1 and other interfaces are provided according to the user interface | The figure below is the outline dimension drawing of the 5.5KW , N1, N2, R1 and other interfaces are provided according to the user interface | |||

|

|

|

| |

|

| |||

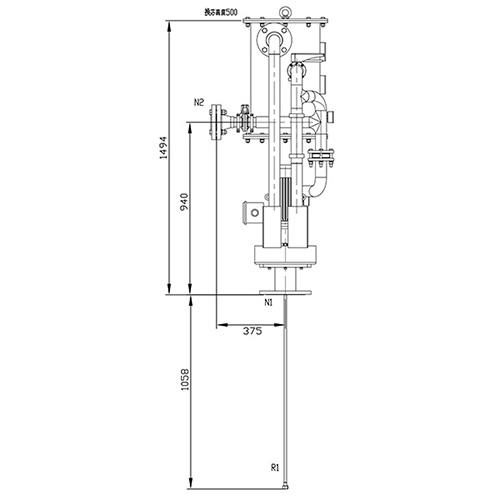

The figure below is the outline dimension drawing of 7.5KW oil mist separator, N1, N2, R1 and other interfaces are provided according to the user interface | ||||

|

| |||

| ||||

OME jet oil mist separator uses 6Bar compressed air as the power source.