Viking heat exchanger product application range

It can be widely used in heating, ventilation and air conditioning (HVAC), energy fields, petrochemicals, iron and steel metallurgy, shipbuilding industry, automobile industry, food and medical, machinery and electronics, textile industry, paper industry and other industries.

In addition to the production and sales of heat exchanger products and spare parts, the company also provides efficient on-site services for various heat exchanger products, including plate cleaning, maintenance, replacement, and heat exchanger troubleshooting, hydraulic pressure , Pipeline testing, etc.

Advantages of plate heat exchanger

Product model naming rules

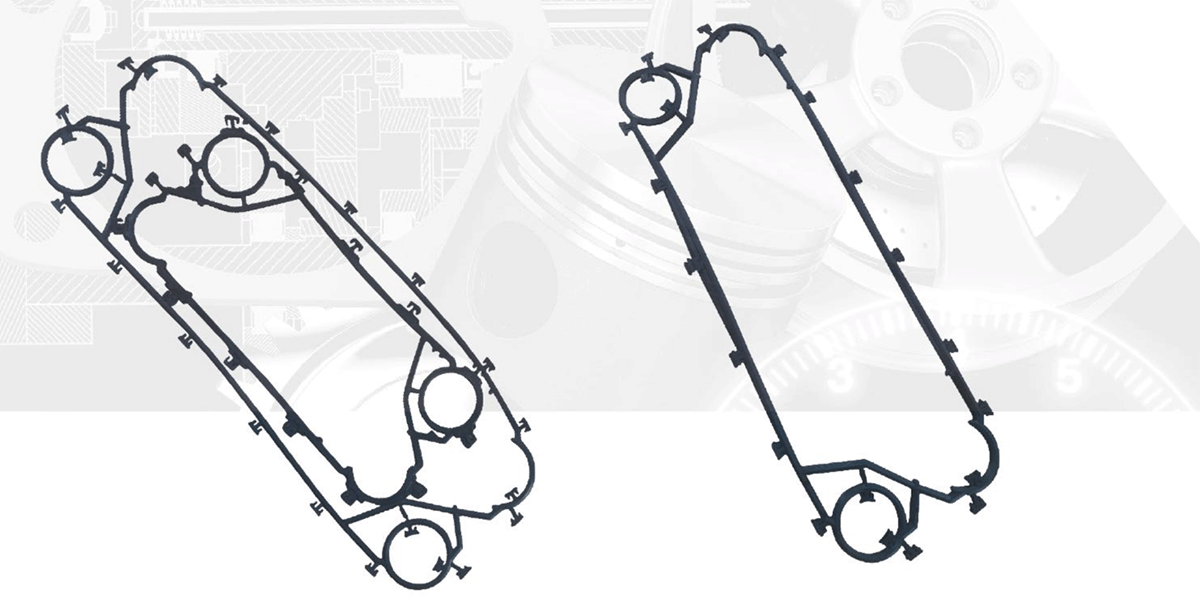

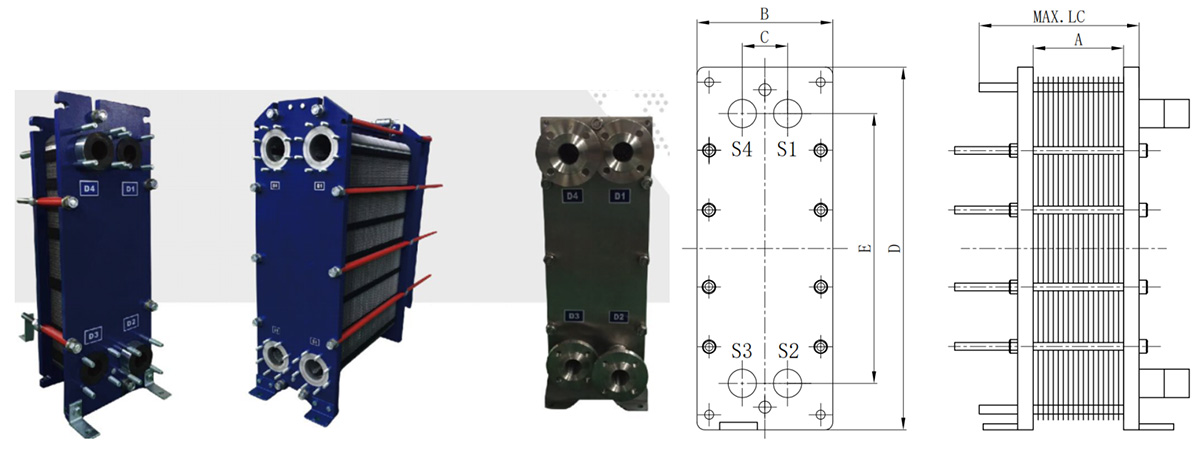

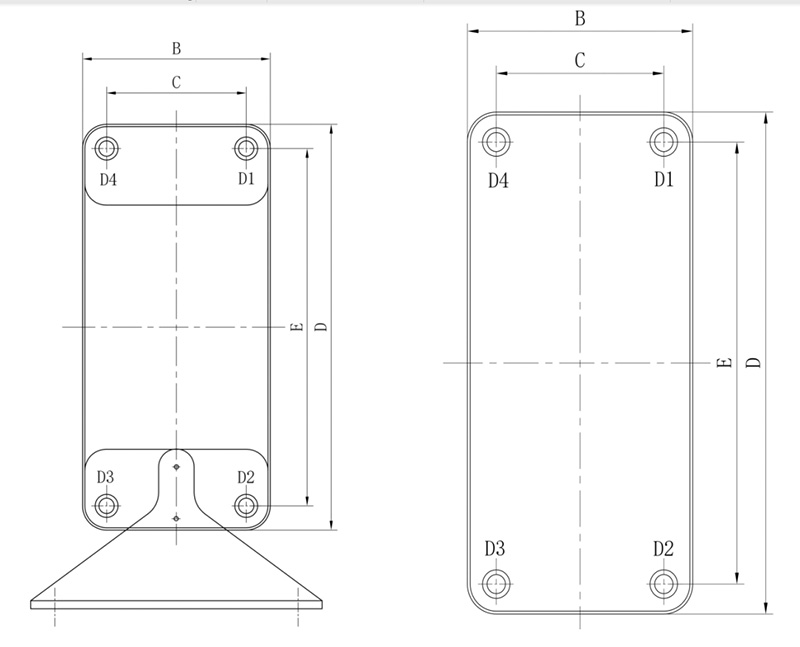

Detachable plate heat exchanger

model | Clamping distance A(mm) | width B(mm) | Take over the horizontal center distance C(mm) | length D(mm) | Take over the longitudinal center distance E(mm) | Height from bottom center to ground (mm) | Maximum installation size(mm) | Interface pass(mm) | Maximum number of pieces | Maximum flow(m³/h) | design pressure(Mpa) |

VK30 | N(2.5+X) | 180 | 60 | 480 | 357 | 62 | 500 | 32 | 95 | 18 | 1 |

VK50 | N(2.4+X) | 300 | 126 | 678 | 394 | 142 | 1200 | 50 | 200 | 36 | 1 |

VK60 | N(2.0+X)/N(3.0+X) | 320 | 140 | 920 | 640 | 140 | 1200 | 50 | 250/203 | 36 | 1.0/1.6 |

VK100 | N(2.55+X)/N(3.0+X) | 470 | 225 | 1069 | 719 | 183/200 | 1600 | 100 | 278/180 | 140 | 1.0/1.6/2.5 |

VKL100 | N(2+X) | 480 | 225 | 1888 | 1338 | 262 | 3000 | 100 | 400 | 140 | 1.0/1.6 |

VK150 | N(2.5+X)/N(3.95+X) | 610 | 298 | 1815 | 1294 | 275 | 3000 | 150 | 600 | 360 | 1.0/1.6/2.5 |

VK200 | N(4+X) | 780 | 353 | 2260 | 1478 | 380 | 3000 | 200 | 400 | 600 | 1.0/1.6 |

VK250 | N(2.5+X) | 920 | 439 | 2895 | 1939 | 435 | 3000 | 250 | 500 | 750 | 1.0/1.6/2.5 |

VK350 | N(3.3+X) | 1150 | 596 | 2882 | 1842 | 470 | 4800 | 350 | 700 | 997 | 1.0/1.6 |

Plate material:304、316L、Ti、Ti-pd、SMO254、C276

Gasket material:NBR、EPDM、F26、FTP

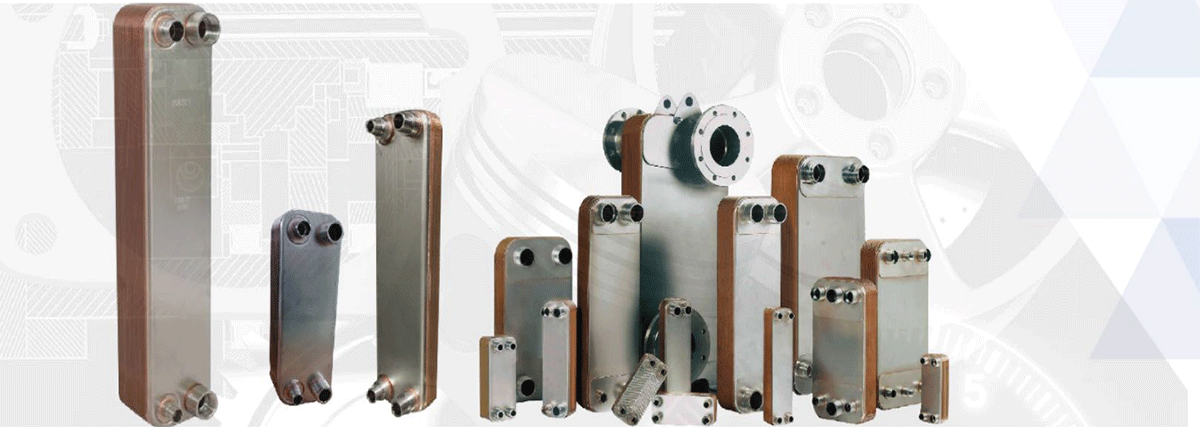

Brazed plate heat exchanger

model | widthB(mm) | Take over the horizontal center distanceC(mm) | Take over the longitudinal center distanceE(mm) | lengthD(mm) | thickness(mm) | weight(kg) | design pressure(Mpa) | Maximum flow(m³/h) | Design temperature(℃) |

VK14 | 76 | 42 | 172 | 206 | 9+2.3N | 0.6+0.056N | 1/3/4.5 | 8 | -195~225 |

VK20B | 78 | 42 | 282 | 318 | 9+2.3N | 0.9+0.088N | 3/4.5 | 8 | -195~225 |

VK20A | 95 | 40 | 269 | 325 | 9+1.58N | 0.9+0.088N | 3/4.5 | 8 | -195~225 |

VK26 | 111 | 50 | 250 | 310 | 10+2.36N | 1.3+0.12N | 3/4.5 | 18 | -195~225 |

VK300 | 124 | 70 | 250 | 304 | 13+2.4N | 2.2+0.146N | 3/4.5 | 18 | -195~225 |

VK52A/B | 111 | 50 | 466 | 525 | 10+2.35N | 1.9+0.215N | 3/4.5 | 18 | -195~225 |

VK62A/B | 119 | 63 | 470 | 526 | 10+2.35N | 2.4+0.225N | 3/4.5 | 18 | -195~225 |

VK95A/B | 191 | 92 | 519 | 616 | 11+2.72 | 6+0.415N | 3/4.5 | 42 | -195~225 |

VK120A/B | 246 | 174 | 456 | 529 | 10+2.36N | 7+0.472N | 3/4.5 | 42 | -195~225 |

VK200A | 321 | 188 | 603 | 738 | 13+2.7N | 13+0.74N | 1.5/2.1/3 | 100 | -195~225 |

VK200B | 321 | 188 | 603 | 738 | 13+2.75N | 13+0.73N | 1.5/2.1/3 | 100 | -195~225 |

model | width(mm) | Take over the horizontal center distance(mm) | length(mm) | Take over longitudinal | Waterway takeover horizontal center distance(mm) | Longitudinal center distance of water pipe(mm) | thickness(mm) | weight(kg) | design pressure(Mpa) | Maximum flow(m³/h) | Design temperature(℃) |

VKL130 | 247 | 161 | 495 | 414 | 172 | 369 | 10+2.15N | 4+0.424N | 3/4.5 | 42 | -195~225 |

VKL250 | 322 | 205.2 | 739 | 631.7 | 224.4 | 568 | 13+2.7N | 16+0.711N | 3/4.5 | 100 | -195~225 |

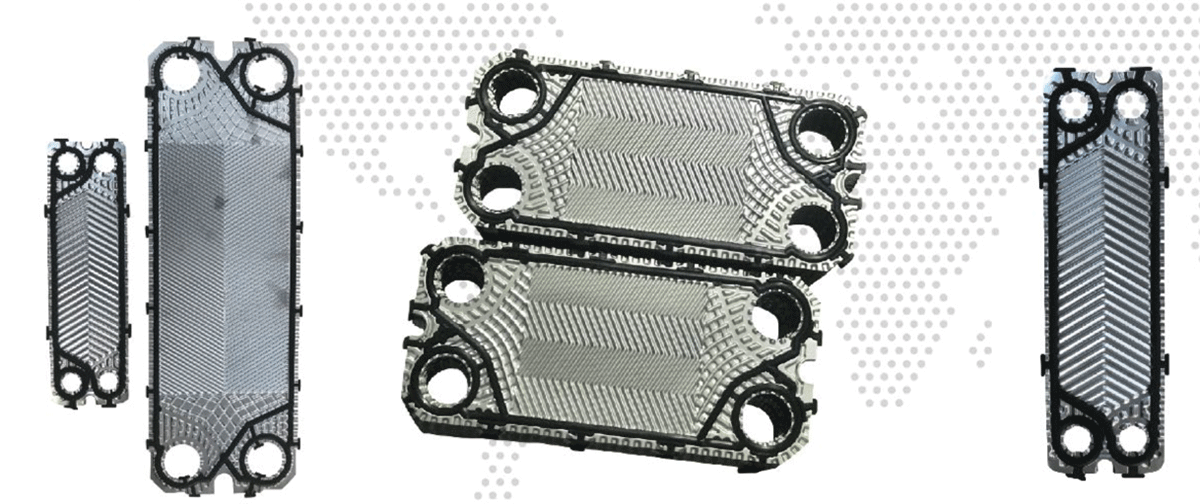

Plate

Material | Suitable for fluids |

HASTLLOY alloy(C276、D205、B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |

(Ti) | Sea water, salt water, salinized water |

(Ni) | High temperature, high concentration of caustic soda |

20Cr、18Ni、6Mo(254SMO) | Dilute sulfuric acid, sparse salt aqueous solution, inorganic aqueous solution |

Stainless steel(Alloy304、ALLoy316.) | Water, steam, lubricating oil |

Sealing rubber pad

Rubber pad material | Operating temperature | Suitable for fluids |

Viton/FKM | -5~180℃ | Acid, alkali, fluid |

HNBR | -15~160℃ | High temperature mineral water, high temperature water |

NBR | -15~110℃ | Water, sea water, mineral oil fume |

EPDM | -25~160℃ | Hot water, steam, acid, alkali |